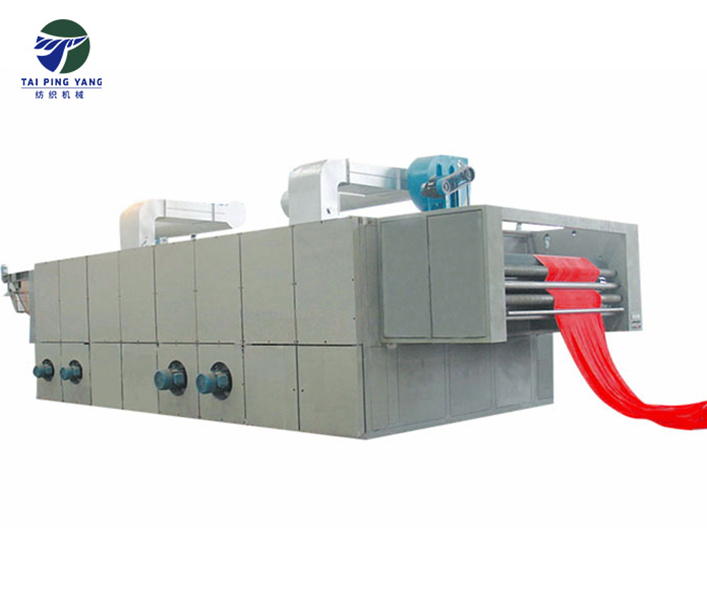

Three pass tensionless dryer

Usage of the tensionless dryer machine:

This machine adopts three pass web belts tensionless drying, the hot air from the large centrifugal blower goes through the fabrics, the fabrics are shrunk through the three layers web belts, during the drying period, the fabrics move in large wave mode, completely non tension.

The fabrics treated by this machine have soft hand-feeling, low water shrinkage and fabrics quality is enhanced. It has the advantage of saving energy、high efficient, high automatic and easy to operate. So it has become one of the most ideal drying devices.

The appearance of the machine is beautiful, the entire frame, chambers, panels are made of super carbon steel, and surface are specially treated.

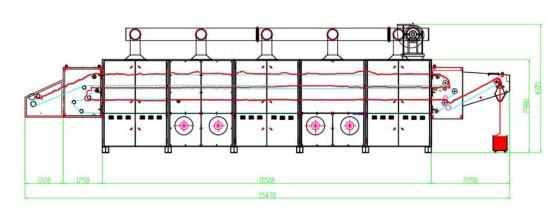

Drawing design:

Technical parameter

Web belt width | 2000MM/2200mm/2400mm/2600mm/2800mm/3000mm/3200mm |

Machinical speed | 5-34M/MIN |

Overfeeding rate | -20 — +50% |

Fabrics length in the drying chambers | 58meters (6.3meters per chamber.) |

Heating dimension of each heat exchanger | 220m² |

Max evaporation capacity | 140 — 180Kg/H·chamber |

Dimension(LXWXH) | 16530X3960mm X4000MM Each chamber length 2100mm |

Chambers quantity | six chambers |

Total weight | 35tons (each chamber 5tons) |

Power | 149.85Kw (each chamber 22kw) |

Machine structure:

Fabrics infeed section

Fabrics exit section

Controlling valve

Thermo oil heating method adopts

Bealz brand electric three way valves that made in Germany

Steam heated:adopts pneumatic direction changing valve.

Heat recycle system

Except the first chamber, the left chambers equips heat recycle sytem per chamber.

Electrical control

1. Electric controls adopts programme controlling method, equips blowers starting in sequence system, faulty fabrics protecting system, emergency cooling system, counter-clockwise system

2. Electric component adopts Taiwan Delta inverter, France Schneider low voltage apparatus. temperature controller brand is Honeywell of America(±3℃).