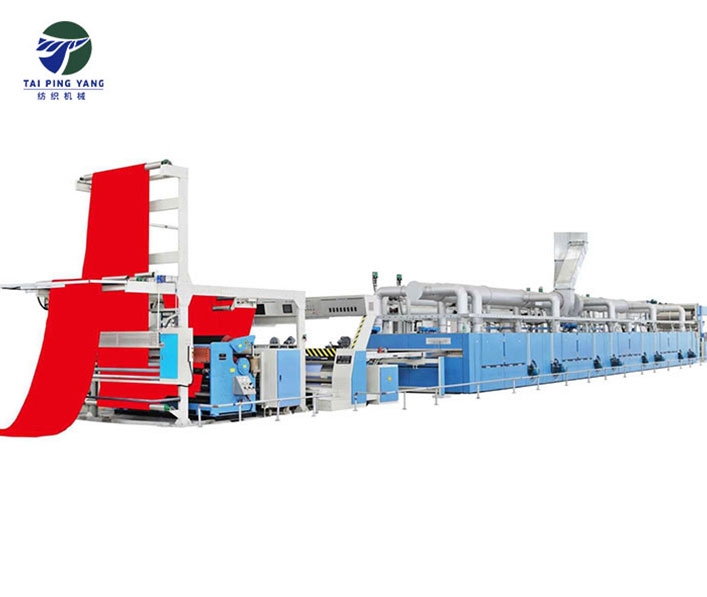

Thermal oil stenter

Stenter(we have stenter both can work for weaving and knitting fabrics).

Machine Usage:

TPYD2800 hot air stenter is mainly used for the cotton, polyester, wool, hemp of setting process for the open width fabrics, after worked by the machine, you can get stable size of the fabrics.

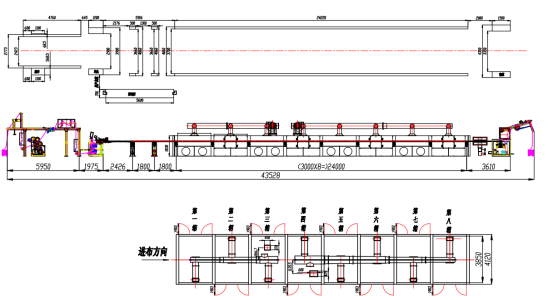

Drawing design :

Mainly technical parameters

Machine working pattern: | chains circulation horizontal rotary |

Heat setting pattern: | hot air circulation |

Chains pattern: | pitch 60mm, stainless steel chains. |

Machine standard power: | 380V(±5%)50Hz3PH |

Control power: | 220V, 24V |

Applicable steam specification: | 3-6Kg/cm²saturated steam |

Steam comsumption | 00~150kg/hour |

Applicable compressed air specification | 0.3-0.6Mpa compressed airwithout moisture |

Maximum temperature of the heating chamber | 220℃ |

Applicable heat sourch | A. Circulation thermal oil |

Circulation oil consumption | 80000-140000Kcal/ H·chamber(0.33-0.6GJ) |

Natural gas consumption | 8-15m³/H·chamber(about6.5-12KG) |

Main chain driven pattern | right and left chains drive seperately |

Working width control pattern | working width of each chamber adjust seperately |

Air delivery pattern of the heating chamber | upper blower chamber and lower blower chamber control air volume seperately. |

Pin plate maximum working width | 2000mm-3000mm |

Heating chamber width | 000mm/chamber |

Machincial speed | 5~80m/min |

Power of some parts | Padder: 12.5kw |

Machine weight | about 12tons+4.5ton/chamberxN chamber |

Machine colour | jewelry blue + Crystal White |

Insulated pannel thickness | 150mm |

Technical flow:

Open width fabrics infeed -- infra red expanding and centering -- padder -- zidond lower overfeeding -- screw expanding -- machincial weft straigtner -- upper overfeeding -- edge spreader -- infra-red inspector -- pin on -- heat setting -- coolant -- pin off -- exit -- plaiter or rolling.