Rope open slitting squeezing machine

Machine usage:

Automatic rope opening slitting squeezing machine apply to rope opening, slitting squeezing process for woven & knit cotton fabric, rayon fabric, poly/cotton fabric, bi-stretch fabric, pante roma, bengaline, denim fabric. One person operate the machine, replace the traditional rope opening machine, slitting machine .dryer, effectively shorten the after-finishing time. Fabric goes through the big squeezing roller, being squeezed out water , can effectively avoid the fabric crease, reducing the fabric moisture to improve efficiency and reduce labor intensity.

Technical parameters:

Driven pattern | Inverter gear reducer motor drive |

Fabrics speed | 0~100m/min(inverter control and adjustable) |

Infeed and exit pattern | Tubular infeed and open width exit |

Voltage | 380V/220V |

Working width | 2200 mm(2200-3400mm) |

Machine weight | About 12.8T |

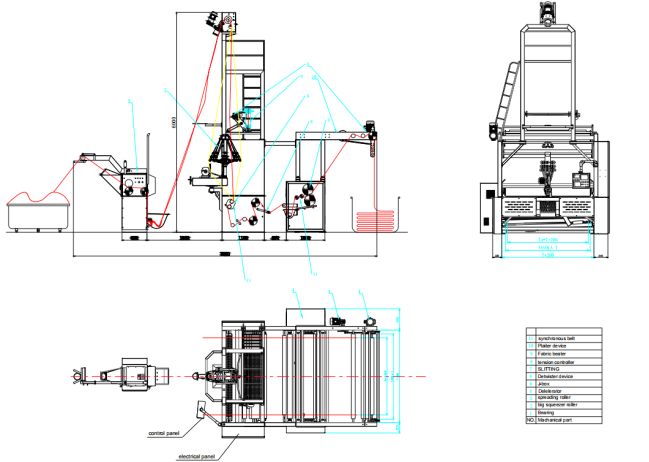

Dimension | L7900*W3500*H6000 |

Drawing design :

Technical advantage:

01 The whole machine is controlled by PLC communication, stable running smoothly when high and low tension simultaneous start. waterproof touch screen, a key to start, easy to operate.

02 The whole machine configuring 8 item security devices to ensure the safety of operating the machine and stability of fabric quality during processing.

03 J-BOX (pre-squeezer) is configurated the latest function: no cloth stop; encountered a cloth knot stop; pressing cloth stop; pulling cloth stop; make the operation more easy and intelligent.

04 The whole machine frame is made of stainless steel 304. Electrical equipment is made from German Siemens brand and reasonable selection and machine is durable.

Working process:

J-box --detwister -Automatic slitting --Tension controller --Fabric beater --Spread roller -Big squeezer roller -plaiting