Tubular Compactor:

Machine usage:

The Tubular Compactor machine is used for preshrinking tubular fabrics, fabrics infeed by magnetic shuttle, while fabrics exit by hydraulic folder(rolling is optional), After compacted by 20mm NOMEX blanket,the fabric could obtain a stable size and less than 3% shrinkage as well as excellent hand feeling and expressive colour.

The Most Significant advantages:

✿ Big compacting size/ high output!!!

✿ Less than 3% washing shrinkage!!!

✿ Nearly do not have creasing mark!!!

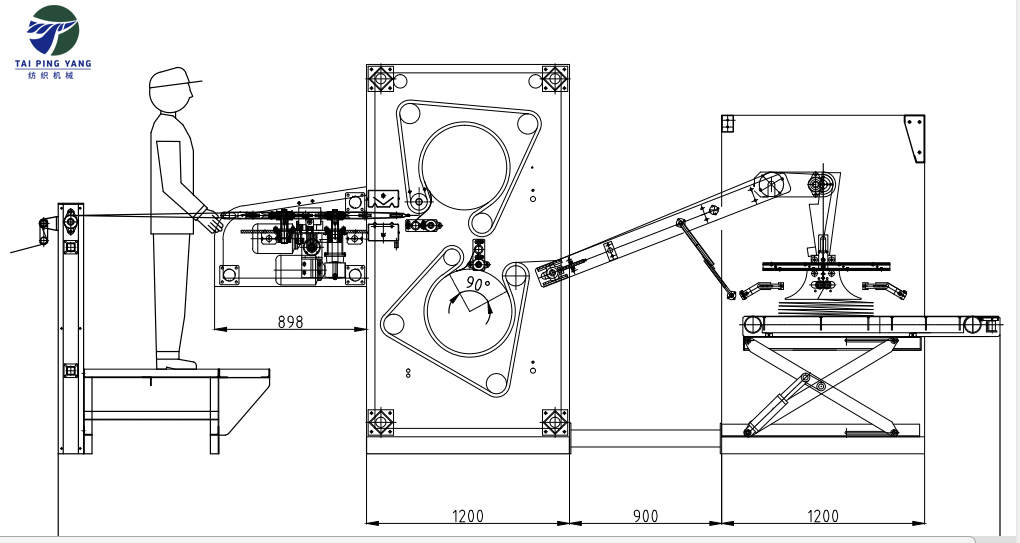

Mechanical Sketch:

Taipingyang Tubular Compactor Advantages:

Compared with our competitors,Dezhou Taipingyang tubular compactor has the following remarkable advantages and it is the reason that most of the company choose our brand,especially for the big group knitting and finishing companies.

▶90%similar as European famous structure.Chinese price with European structure.

▶Higher daily output. 270° wrap angle for compacting units, big compacting area.The daily output is about 8tons.

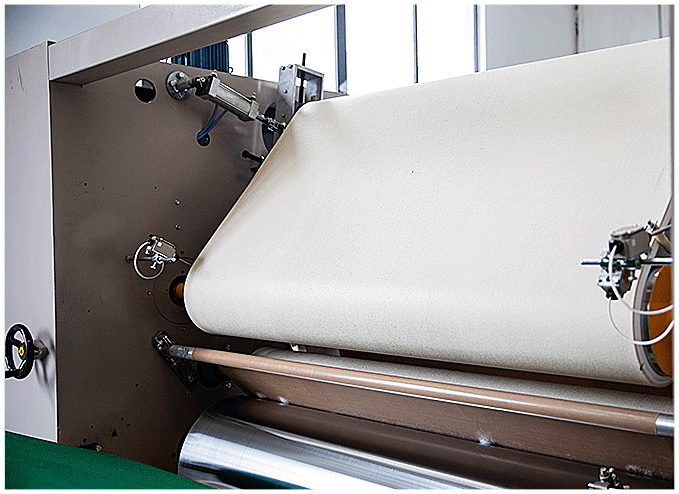

▶Radial shrinkage is less than 3% by 20mm felt and special compacting design. Compacting felt is 20mm thickness,wrap angles by four deflection adjusting roller ,worked with Teflon to realize preshrinking,equip with tension sensor,the tension force is automatically adjusted radial shrinkage is less than 3%.

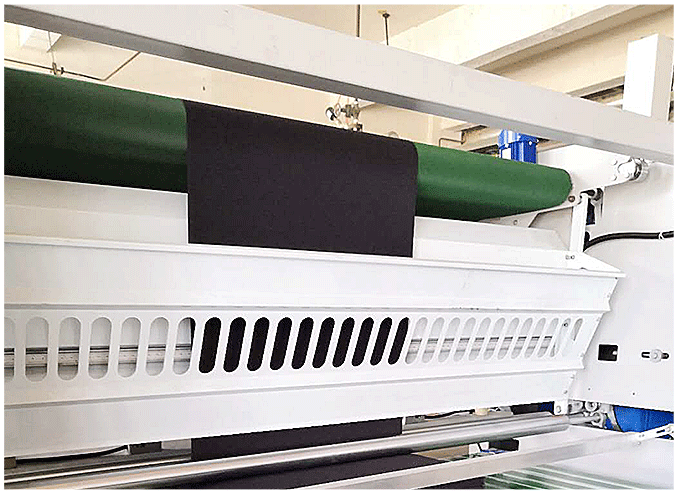

▶Truely magnetic levitation shuttle plate,working width controlled within 2.5mm tolerance.

▶Weft screw is well controlled.The two magnetic levitation is controlled by two motors separately,the belt of the shuttle plate delivery fabrics actively,so it will control the weft screw remarkably.

▶Entrance side equip with hole sensor,if the fabrics has hole,the tubular compacting machine will stop automatically.

▶Faulty display automatically,easy to maintain.

▶SS double nozzle steam box.moisturizer is uniform/evenly.

▶Remote control is optional.iEquip with PLC and touch screen control system,could realize remote control.

▶ Equips with working width value online inspection system,which could control the working width effectively.

▶Exit is hydraulic type precise folding,fabrics exit automatically.

Machine Parts Photos:

Customer Needs To Confirm the Following Information Before Buying:

What is your heating source?

Electric,thermal oil and steam. Steam Max. Temperature is 140°C. While others two are 180°C

What is your working width?

1500mm max and can be customize by your request.

Do you prefer single pass or double pass?

Depends on your fabrics width and output.

Do you need precise folding or rolling exit?

Our standard configuration is precise folding.

Do you need PLC remote device to solve problems online?

It is very Convenient

Enquiry Now: